Is 3D CNC Milling the Future of Manufacturing?

Introduction

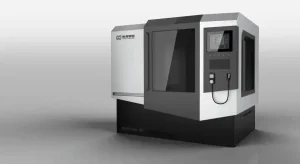

Manufacturing has come a long way over the years, and with the development of 3D CNC milling technology, the future looks even more promising. 3D CNC milling is a cutting-edge manufacturing process that allows for the creation of complex and intricate parts with a high level of precision. This article will explore the potential of 3D CNC milling and its role in shaping the future of manufacturing.

The Advantages of 3D CNC Milling

3D CNC milling offers a wide range of advantages over traditional manufacturing methods. Some of the key benefits include:

- Precision: 3D CNC milling machines are capable of producing highly precise parts with tight tolerances, ensuring high-quality results.

- Complexity: This technology enables the production of complex geometries and intricate designs that would be difficult or impossible to achieve with traditional methods.

- Efficiency: 3D CNC milling streamlines the manufacturing process, reducing production time and costs while increasing overall productivity.

- Materials: A wide variety of materials can be used in 3D CNC milling, including metals, plastics, and composites, providing flexibility and versatility in manufacturing.

The Future of Manufacturing

As technology continues to advance, 3D CNC milling is poised to play a significant role in the future of manufacturing. With its ability to produce high-quality, complex parts at a rapid pace, this technology is revolutionizing the industry in several ways.

One of the most significant impacts of 3D CNC milling is its potential to transform the prototyping process. In the past, prototyping new parts or products required time-consuming and costly tooling and machining. With 3D CNC milling, however, prototypes can be quickly and accurately produced, allowing for rapid iteration and refinement of designs. This not only speeds up the development process but also reduces the overall cost of prototyping.

Additionally, 3D CNC milling offers the ability to produce custom and on-demand parts with ease. This opens up new possibilities for personalized products and localized manufacturing, as it eliminates the need for large-scale production runs and massive inventories. As consumer demand for customized products continues to grow, 3D CNC milling provides a viable solution for meeting these needs.

Conclusion

As the manufacturing industry continues to evolve, the importance of 3D CNC milling cannot be overstated. Its ability to deliver precision, complexity, efficiency, and versatility makes it a key player in shaping the future of manufacturing. With advancements in technology and the ongoing demand for high-quality, customized products, 3D CNC milling is undoubtedly at the forefront of the industry’s future.

FAQs

What materials can be used in 3D CNC milling?

3D CNC milling can work with a wide variety of materials, including metals, plastics, composites, and wood. This versatility makes it suitable for a broad range of manufacturing applications.

How precise is 3D CNC milling?

3D CNC milling machines are capable of producing highly precise parts with tight tolerances, often within a few microns. This level of precision makes it ideal for applications that require exacting specifications.